Success by design

All info on this page was taken from the Winter 1998 edition of Torque (the magazine of the Riders Association of Triumph - RAT)

TRIUMPH's new Sprint ST sports tourer follows in the footsteps of one of the most popular motorcycles ever produced by the Hinckley factory, but its design involves some major developments from the original machine.

The design team responsible for the Sprint ST was given a demanding brief : produce the most sophisticated Triumph to date in terms of driveability and ease of use, but exceed the sport touring sector's benchmark standards for power, performance, handling, braking, comfort, fuel economy and weather protection; introduce an element of engine 'character' into a sector where the machines were seen by some as being too bland; achieve all this at a price within a few per cent of the market leading machines. Simple!

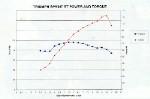

That sort of performance from an engine with 130PS potential ensures a relaxed, highly efficient unit with the inherent character of a triple and a huge spread of torque.

The ST's engine produces more than 80 Nm (60 lb.ft) of torque from just over 3500 rpm right up to 9500 rpm, with a peak of 95Nm (70 lb.ft) at just 6000 rpm. This is achieved with a smooth power delivery devoid of flat spots throughout the rev range thanks to the work put into setting up the engine management system to ensure exceptionally good transfer between the points on the fuel injection mapping.

The resulting highly efficient engine not only produced the required character, it returned amazing fuel consumption figures. For example, at a steady l2Okph (75mph), the Sprint ST will return over 50mpg (around 5.2 litres per 100km), and on one route used by Triumph's testers it returned 56mpg (4.9 litres per 100km) where a leading competitor could only manage 38mpg (7.5 litres per 100km). One result is a touring capacity of 250 miles-plus between refills.

But the work went beyond achieving just power and efficiency. Much attention was paid to the amount and type of noise the machine produced. The new twin spar frame provides natural sound insulation around the airbox, while new curved air intakes reduce noise levels and a noise suppression block at the back of the crankcase deadens gear and sprag drive noise.

The result is a superbly 'rider-friendly' engine which nevertheless retains excellent all-round performance.

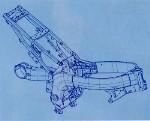

This gives various advantages. It allows enough space above the engine for the fuel injection system; it is extremely stiff and enables a reduction in the number of engine mounting points from eight to six; it reduces weight and the amount of heat transmitted to the frame from the engine.

It also allows the retention of the Daytona's low centre of gravity, despite the lifting of the Sprint's engine to allow the exhaust to be packaged inside the bodywork, and gives the machine class-leading ground clearance.

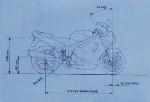

Chassis geometry is designed to oprimise stability, especially when carrying luggage, while an increased wheelbase over the Daytona specification offers not only enhanced stability, but impressively light steering that exceeds original expectations.

The Daytona's single sided swinging arm proved ideal for the Sprint and to add versatility with regards to pannier carrying capacity, the design includes a moveable exhaust that can be raised with the panniers removed to allow increased ground clearance for sports riding.

Aerodynamically, the Sprint received more attention than any previous Triumph. Air flow to the radiator and engine benefits from this work, but so does the rider, with reduced wind noise and a smoothed out slipstream and impressive weather protection.

The engine was based on the well understood 955i unit, so development centred on refining the fuel injection system through a combination on bench testing and feedback from Triumph's development riders.

Frame development followed two paths. The new twin spar frame was originally constructed as a model to check its style, then its dimensions were digitised on computer using a touch probe which can record the position of its tip in three dimensions at the touch of a button.

An engineering Computer Assisted Design (CAD) model was then generated to assess the strength and stiffness of the digital frame using Finite Element Analysis, a computer method which treats the frame as if it were a collection of tiny individual pieces connected together. All this information allowed Triumph's engineers to optimise the strength of various areas of the frame while keeping weight to a minimum.

Meanwhile, the geometry of the frame was road tested by altering a 955i frame to the Sprint's wheelbase, rake and trail figures and riding it on test tracks and set test routes on public roads. Race track testing was carried out later in the programme to ensure that the limits of possible use were considered.

The result is a machine that Triumph are confident will meet the needs of even the most demanding riders.